Care

Responsible Denim for A Better Tomorrow

We believe sustainability should not be limited to some products, infact it’s our foremost responsibility to make every product sustainable.

And, to do so, we need to adopt sustainability as a habit, as a mission, as a part of every step which we take towards introducing

the new innovations & this is the only way forward.

Sustainable Raw Material

Fiber is the core of every textile product. At Kassim, we are trying to use only sustainable fibers in our denim fabrics, these can be GOTS certified organic cotton, GRS certified recycled cotton, recycled polyester & other alternatives like HEMP etc.

Waste isn’t waste until you waste it

In order to meet the demands of recycled cotton, we have setup a GRS certified shredding plant to transform used apparels into useful fibers.

Renewable Energy

50% of our energy needs are fulfilled by the renewable energy source, produced by our 5-Megawatt solar energy setup and our aim is to increase it to 80% by 2024. This is accordance with “UN fashion industry charter for climate action” i-e to drive the fashion industry to net zero greenhouse gas emission no later than 2050, in line with keeping global warming below 1.5C from pre-industrial levels set out in the Paris agreement.

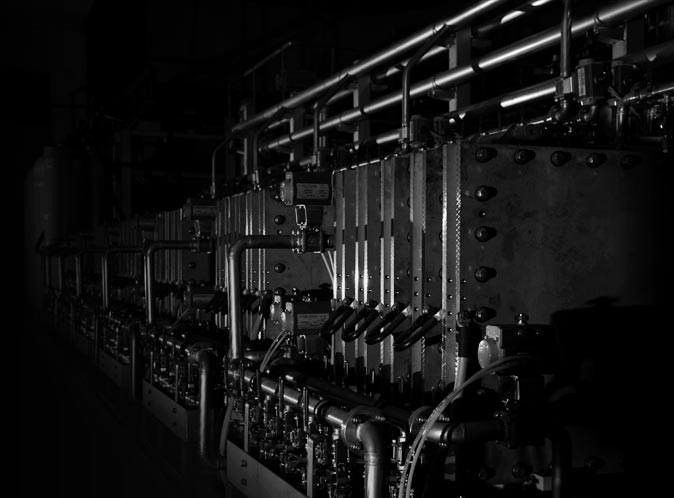

SMART Indigo Dyeing

SMART Indigo has revolutionized not only the way indigo is made but also the whole dyeing process that follows. This process employs a technology that reduces indigo using, it is an electro-chemical process without the need of any harmful chemical.

Our SMART indigo dyeing machines are powered entirely through solar power & the only waste they produce is pure oxygen. The revolutionary process creates indigo that has a higher yield, it reduces color variation & it also decreases the use of salt contents required in the dyeing process.

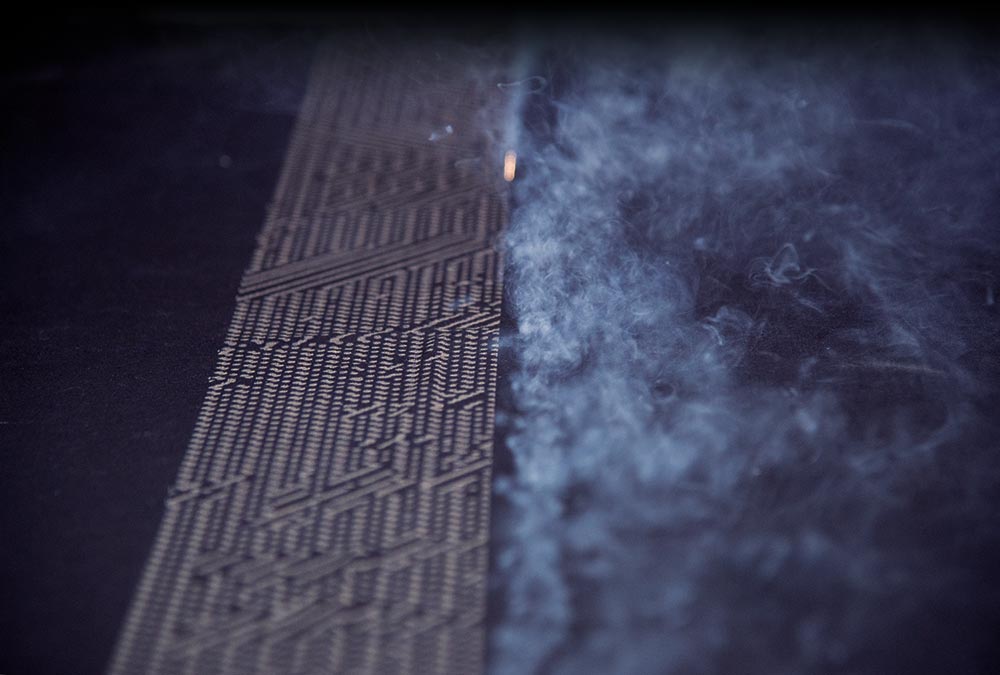

Laser friendly fabrics/Atomic series

Denim Enthusiasts at Kassim have introduced Atomic, a process flow that reduces the dye usage, eliminates the dry process & accelerates the time to market our denim products.

At the yarn stage, we play with the twist and dye the yarn to the surface only, this eradicates the dry process and makes the fabric cordial to laser. We can achieve the desired whiskers, chevrons, scrapping and blast effects similar to the dry process done by hands, making the manufacturing process more environmentally viable, socially responsible & financially sound.